Leo Surface Coating and Eisenmann GmbH Formalise Strategic Partnership in India

In August 2023, Leo Surface Coating Pvt. Ltd. and Eisenmann GmbH formalized their partnership by signing an agreement to collaborate on Eisenmann's operations in India.

Eisenmann is a globally recognized supplier of industrial paint shops, having collaborated with major companies like Volvo, Mahindra & Mahindra, and Mercedes-Benz. Meanwhile, Leo has established itself as one of India's leading suppliers in this sector, boasting over 23 years of experience and a client roster that includes Tata Motors, TAFE, Kobelco, and Wipro.

This strategic alliance aims to leverage the strengths of both companies to deliver high-quality, cutting-edge paint shop facilities. By combining their expertise, Leo and Eisenmann intend to create synergies that enhance operational efficiency and innovation in the Indian market.

Paint Separation with Vision: E-Cube, a sustainable and efficient solution

E-Cube is an innovative paint separation system that offers numerous advantages for coating operations. It operates without the need for chemicals, water, or other additives, significantly reducing waste disposal costs and environmental impact. The system achieves a remarkable separation efficiency of over 99%, ensuring that exhaust air quality meets stringent international standards. With energy savings of up to 42% compared to traditional Venturi wet scrubbers, E-Cube not only enhances operational efficiency but also lowers initial investment costs by up to 24%. Its modular design allows for easy installation and maintenance, enabling filter replacements during ongoing operations in under five minutes. This user-friendly approach requires no specialized training, making it accessible for all personnel.

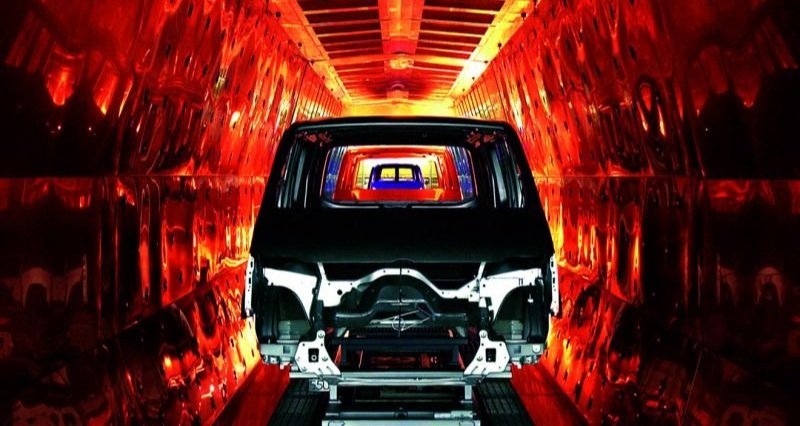

Patented E-Shuttle Conveyor Systems for Dip Coating

Eisenmann specialises in innovative conveyor systems for dip coating, crucial for achieving high surface quality in automotive manufacturing. Since introducing the first full-body dip pretreatment system in 1978, Eisenmann has focused on developing flexible and intelligent conveyor technologies tailored to the specific needs of vehicle bodies. Their comprehensive portfolio includes various conveyor types, such as the E-Shuttle 200 and E-Shuttle 300, designed for efficient and customisable coating processes. These systems enhance production efficiency by allowing precise control over immersion curves and process times while minimizing operating costs through reduced water and chemical consumption. Eisenmann's commitment to flexibility and sustainability positions them as a leader in the automotive coating industry.

Other Eisenmann Products

Efficient drying and curing processes are essential for achieving long-lasting, high-quality coatings in automotive applications. The development of smart dryer systems is a key focus, as curing plays a critical role alongside paint application. The industry demands energy-efficient and resource-saving solutions to meet these needs.

Paint Curing Technology

Eisenmann offers a range of conveyor systems designed to optimise the coating process and enhance overall factory efficiency. These systems are designed to handle various car body types and sizes, ensuring flexibility and scalability.

Conveyer Systems

A Clean and Efficient Solution for Overspray Removal. Spray painting inevitably leads to overspray, the loss of coating material. To maintain the efficiency and longevity of coating systems, reliable overspray removal is crucial.